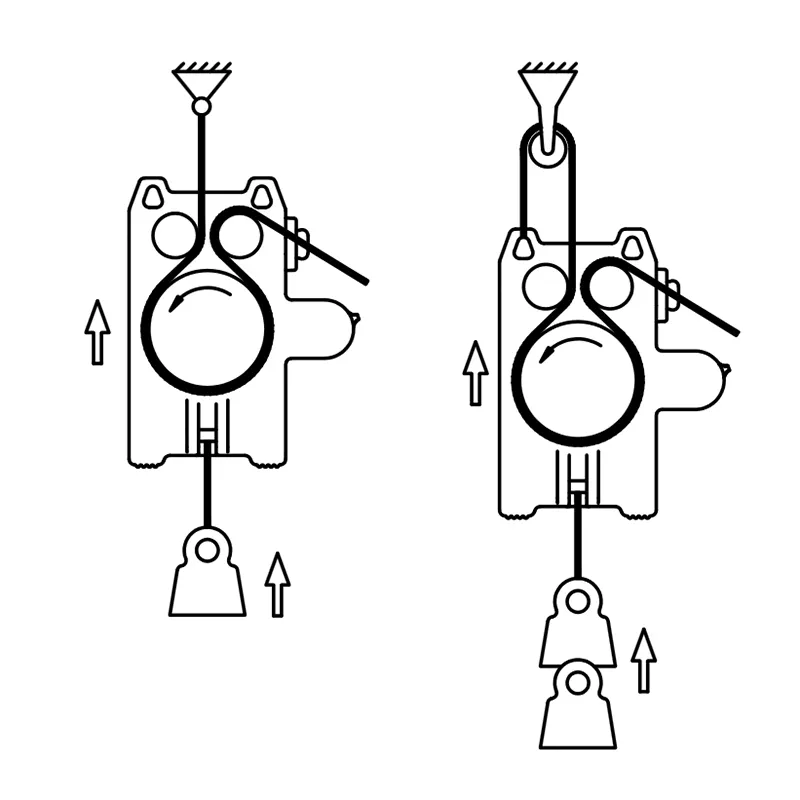

In the standard setup, both the ascender and the load move together, allowing the operator to ascend or descend along with the ascender. This can be managed using the control buttons on the ascender or the remote control. Adding a pulley at the anchor point when the load is up to twice the rated capacity can enhance its lifting capabilities, making it ideal for construction and maintenance tasks where the operator moves with the equipment.

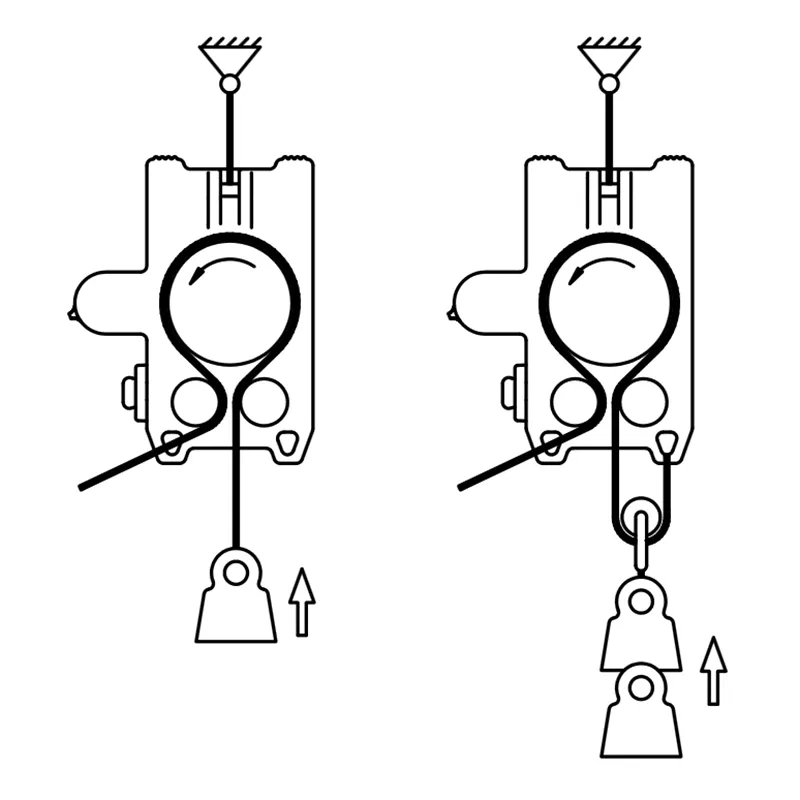

This setup involves fixing the ascender to a lifting platform and winding the rope to lift the load, allowing the operator to stay stationary. This method optimizes the ascender’s power for lifting heavy equipment or materials without requiring the operator to move with the load. It’s particularly useful for lifting tasks in controlled environments. This setup can be controlled using the ascender's buttons or the remote control. When the load is up to twice the rated capacity, adding a pulley at the anchor point can increase the lifting capacity of the ascender.

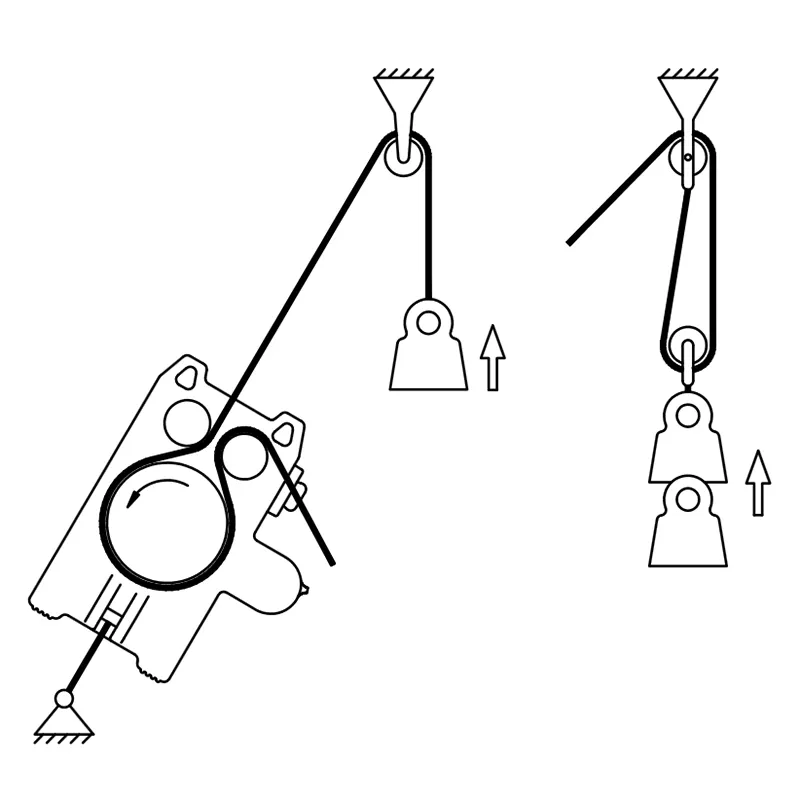

The ascender is fixed to the ground, with a pulley on the lifting platform. The rope passes through the pulley, allowing the load to be lifted efficiently. The operator remains stationary, maximizing the ascender’s lifting power. This method can be controlled via the ascender's buttons or the remote control. Using a pulley system can significantly boost the lifting capacity when handling loads exceeding the rated capacity.

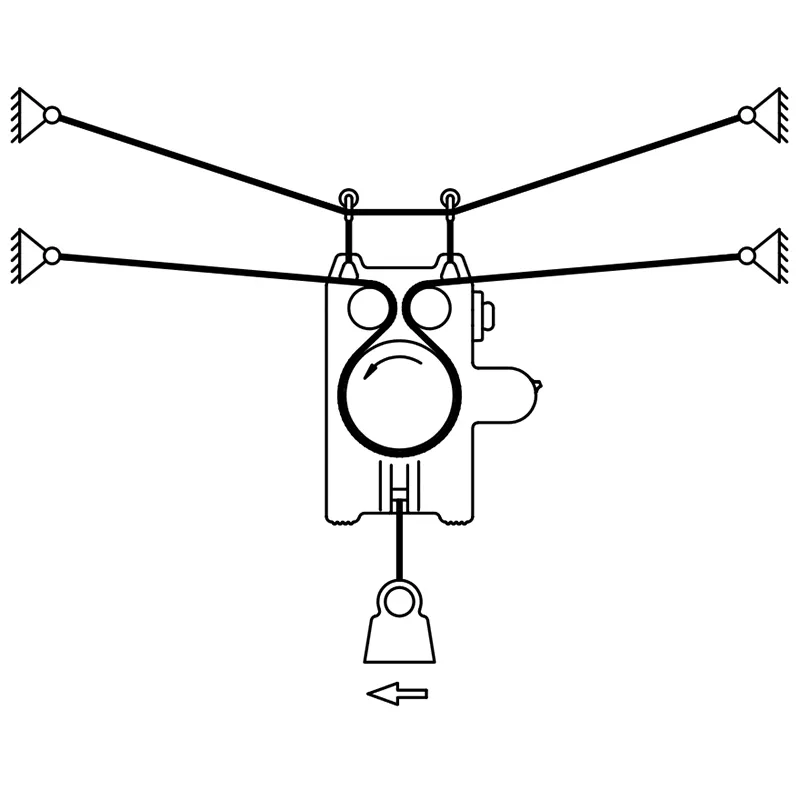

In this setup, the ascender is suspended between two anchor points, enabling horizontal movement. Controlled via remote or the ascender’s controls, this method allows for efficient lateral transfers of loads. It is ideal for rescue operations or tasks requiring horizontal movement across spans.